Petrochemical

We are the industry-leading designer and supplier of highly specialized valve solutions for petrochemical plants and refineries.

Safe and reliable valves for critical service

Vexve is the leading European provider of valve solutions for the energy sector and selected energy-intensive industries. In our Petrochemical segment we offer tailor-made valves for critical service applications for the petrochemical plants and refineries.

Building on our decades of experience in the ethylene, chemical industry and refineries, our world-leading valve technologies meet the highest customer demands. Our safe and cost-effective valve design optimizes the plant performance while simultaneously reducing carbon emissions of the process.

Our specialty is large valves that operate in high temperatures and have high operation frequency, yet very long maintenance interval, resulting to a low cost of ownership.

- Brands:

- Vexve ZMK

- Main products:

- Double disc gate valve, single disc gate valve, butterfly valves, (special) check valves, goggle valves

- Applications:

- Ethylene, delayed coking, catofin (propane dehydrogenation), fluidised catalytic cracking (FCC)

Product highlights

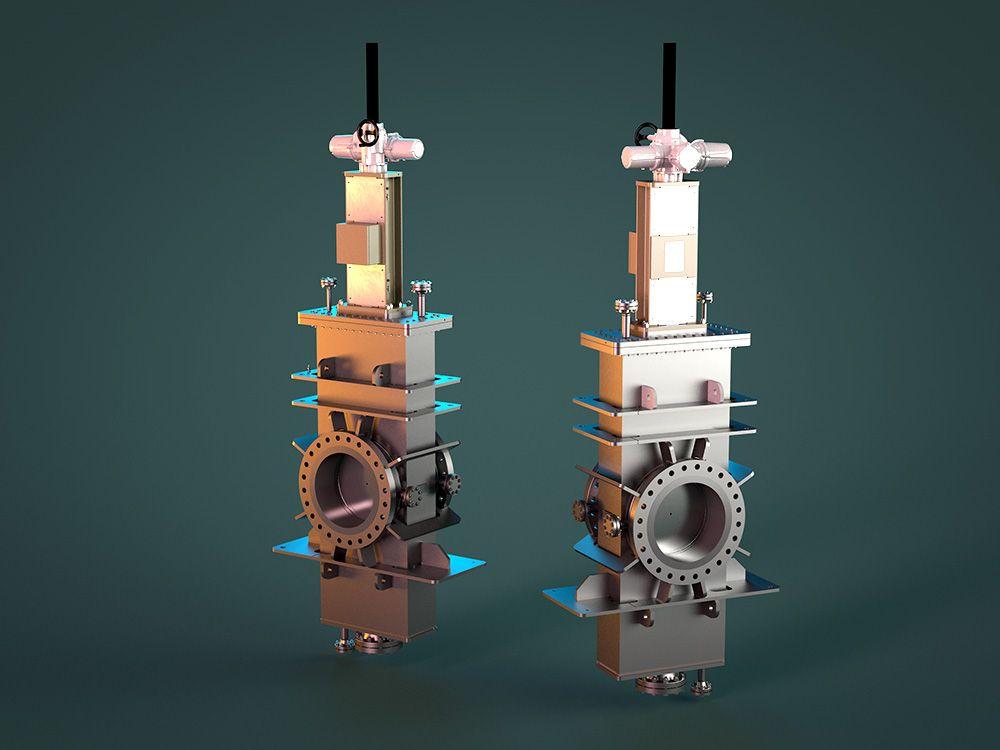

Double Disc Gate Valve

Double disc design valves with metal-to-metal seating provide safe and reliable sealing. They can be used in the most severe refining and petrochemical applications such as fluidized catalytic cracking (FCC), ethylene and delayed coking (DC). Valves for ethylene service are equipped with patented BAFFLE erosion prevention technology.

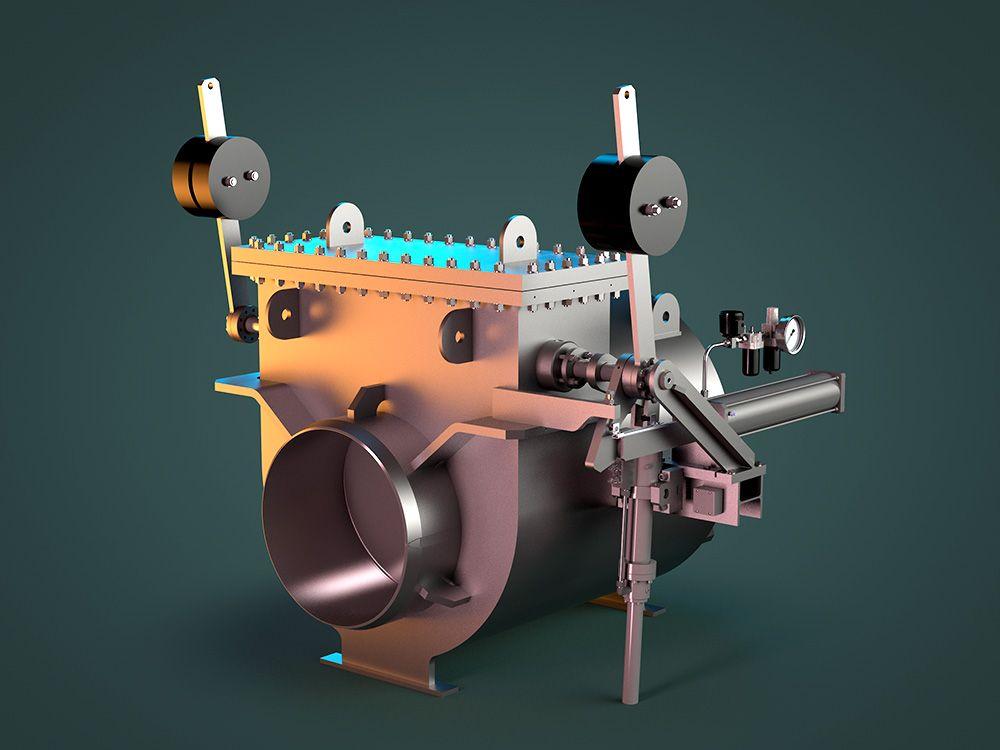

Butterfly valve

Control and shut-off butterfly valves that meet even the most demanding customer needs whether it’s special material or refractory lining that is needed for high-temperature service.

Check valve

Check valves are ideal for in-line maintenance, high temperature services and low differential pressure losses. Flexible and reliable design that guarantees a long service life.

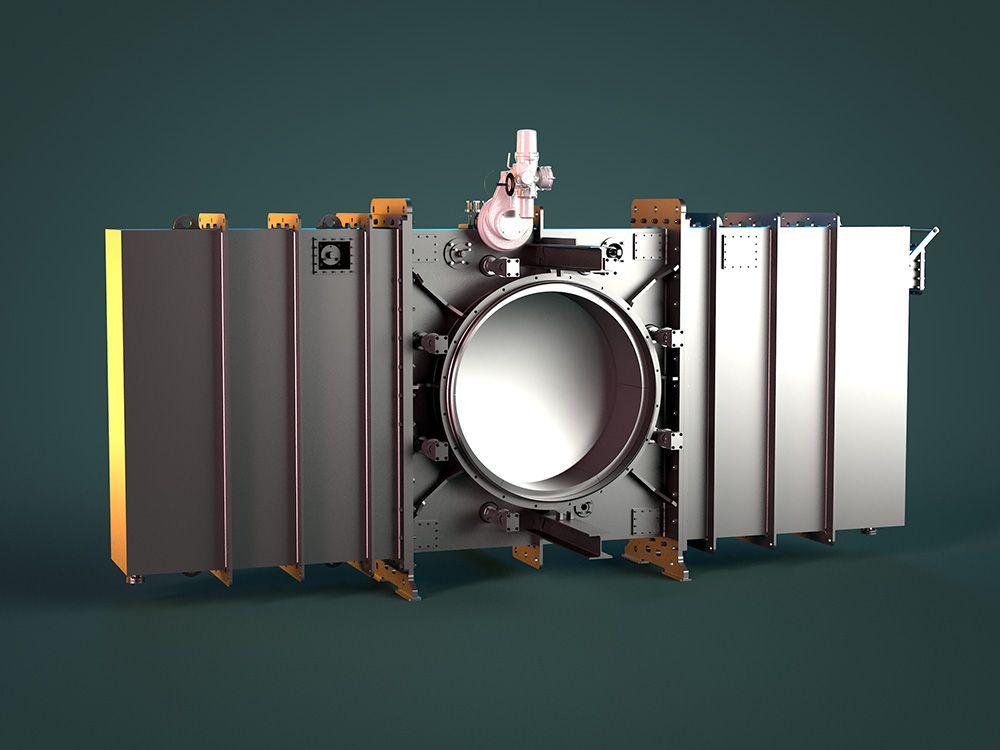

Isolation goggle valve

Goggle valves with 100% shut-off tightness guarantee a total separation of the medium in the closed position ensuring safe maintenance and inspections in high-temperatures and/or toxic gas pipelines.

Vexve ZMK

Ingo Leufgen

Director, Petrochemical and Iron & Steel

+49 17 28 45 58 72

ingo.leufgen@vexve.com

Industries

Iron & Steel, Petrochemical

Represented brands

- Vexve Armatury

- Vexve ZMK